EL-RAK: Exterior Loading Racking System

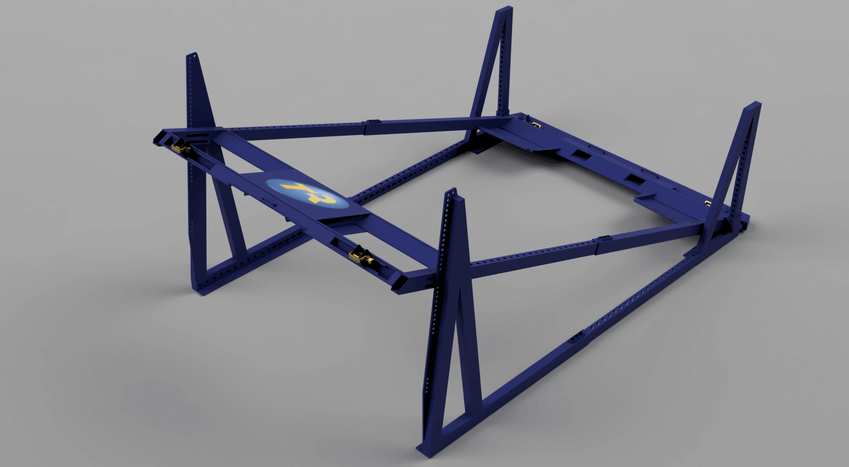

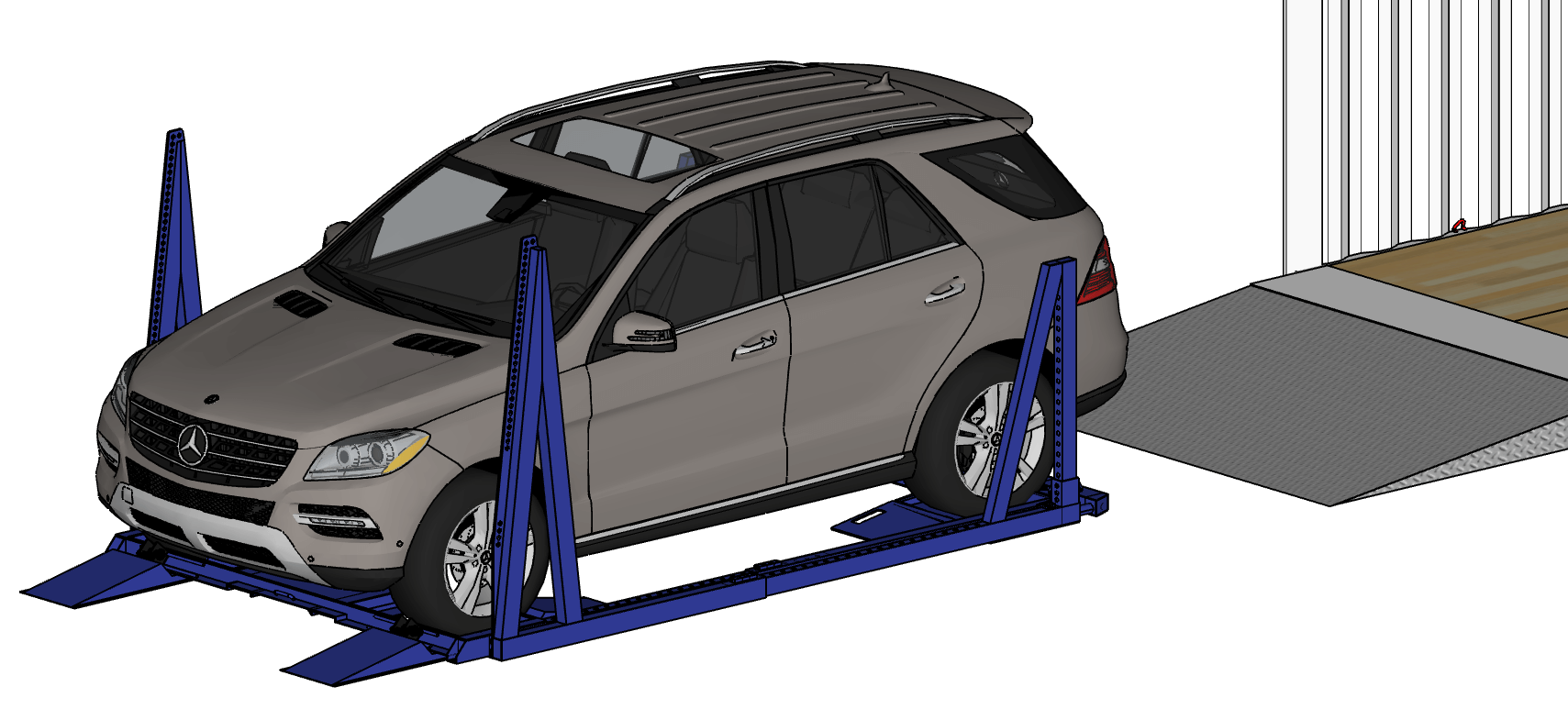

The EL-RAK is the latest product from Trans-Rak and allows for vehicles of any shape or size to be loaded and secured outside the container. We have taken the successful philosophy of the R-RAK and used our expertise to expand into the external loading market.

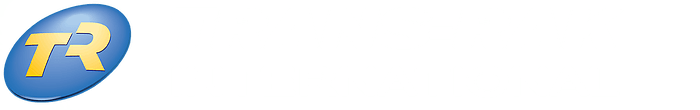

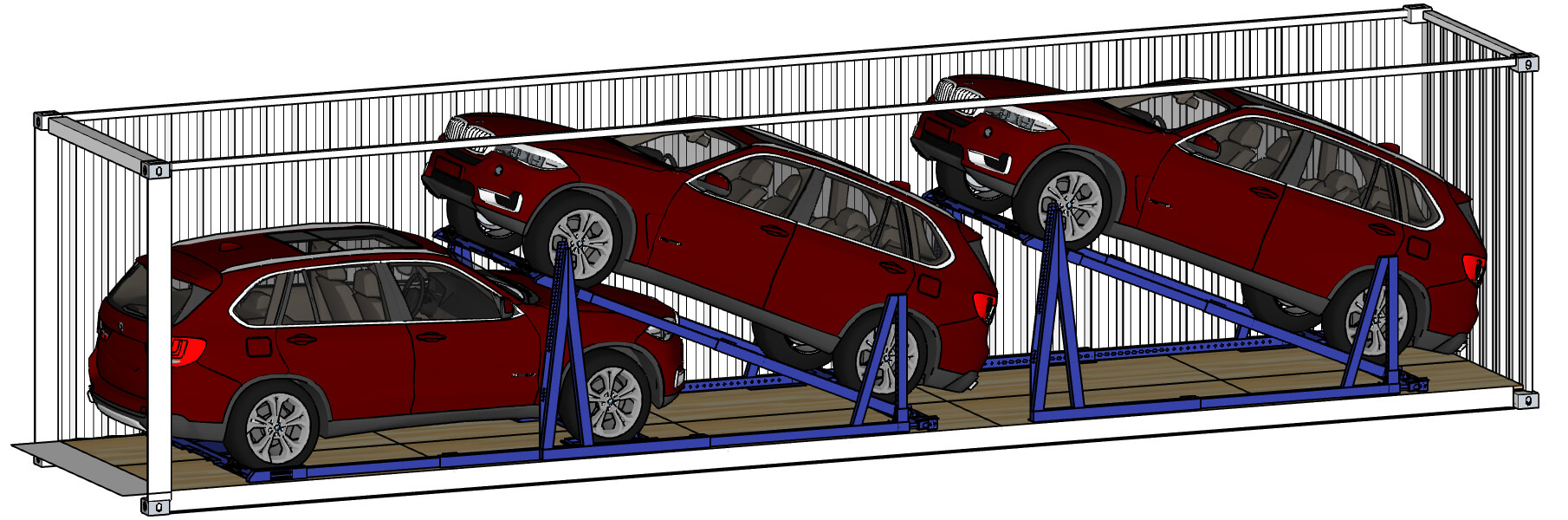

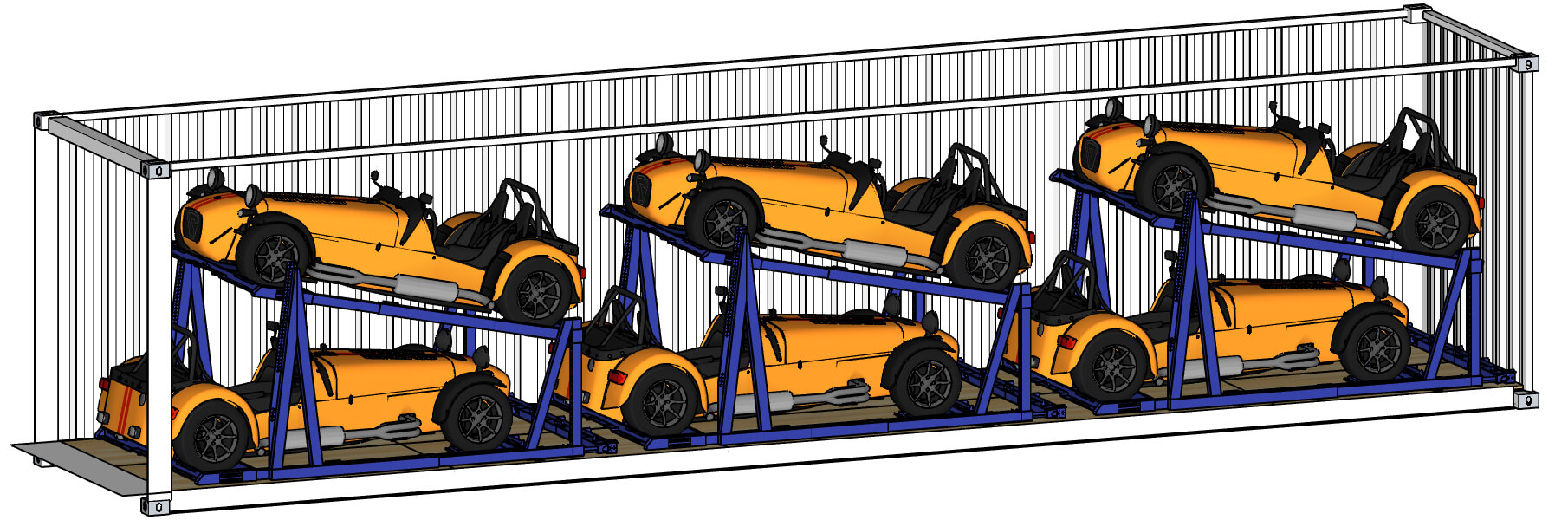

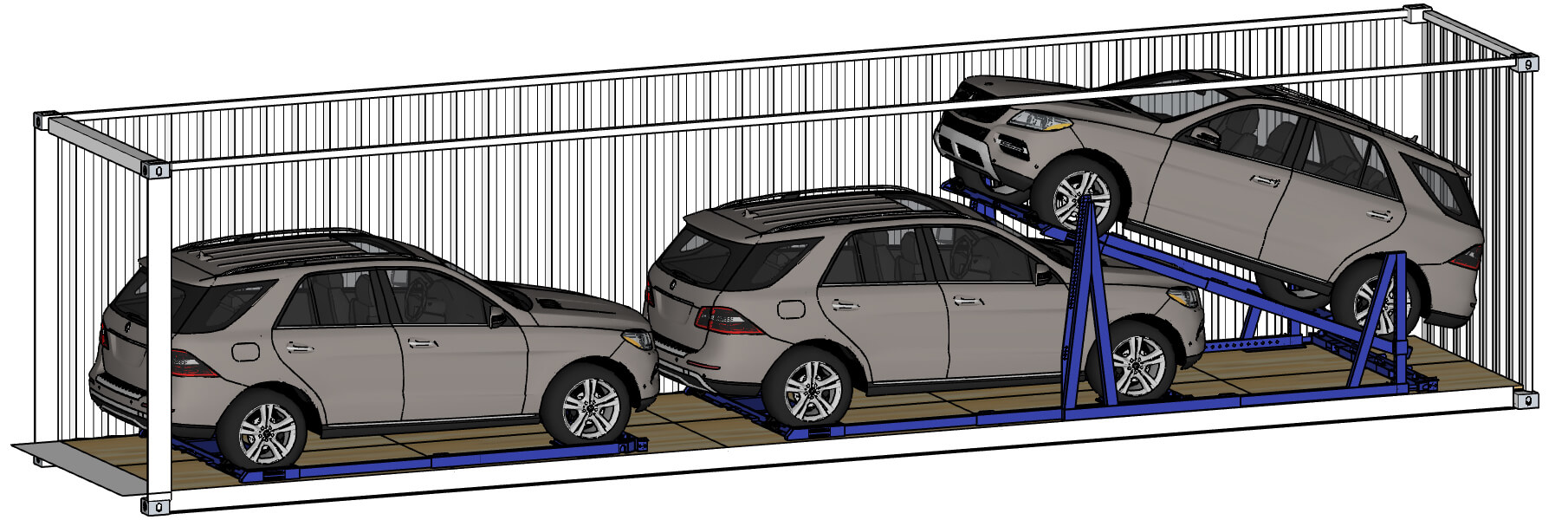

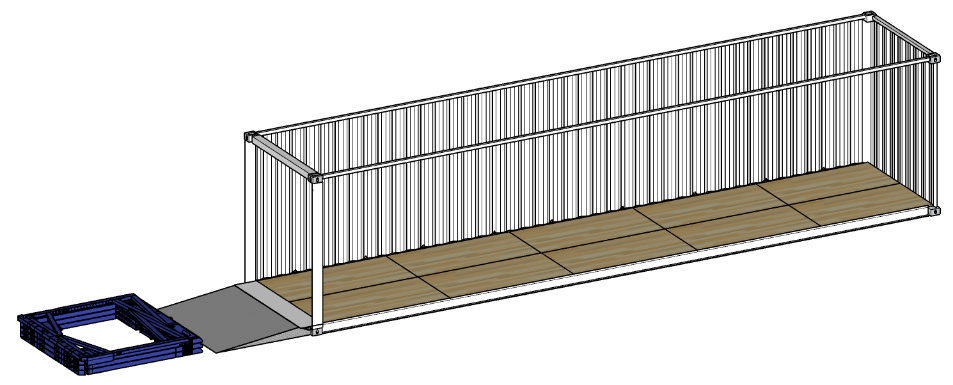

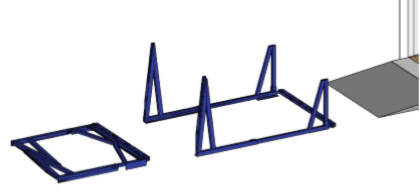

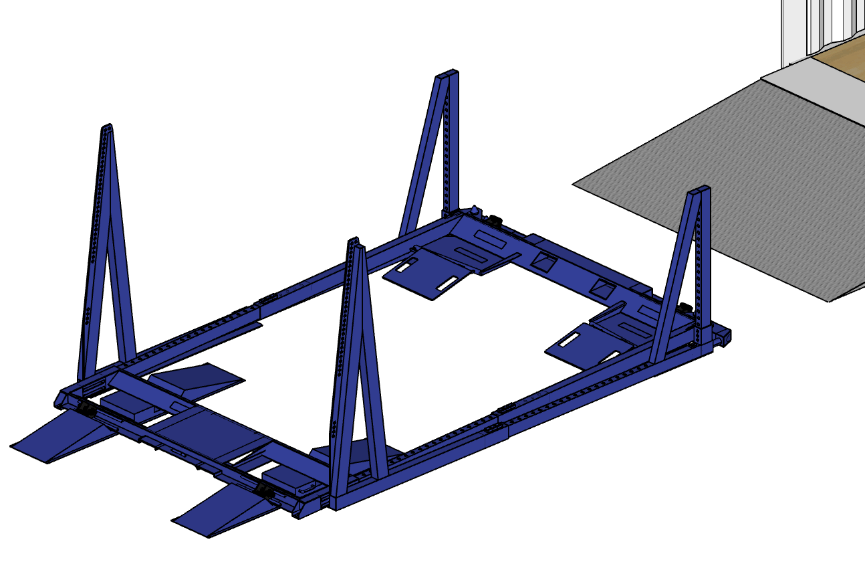

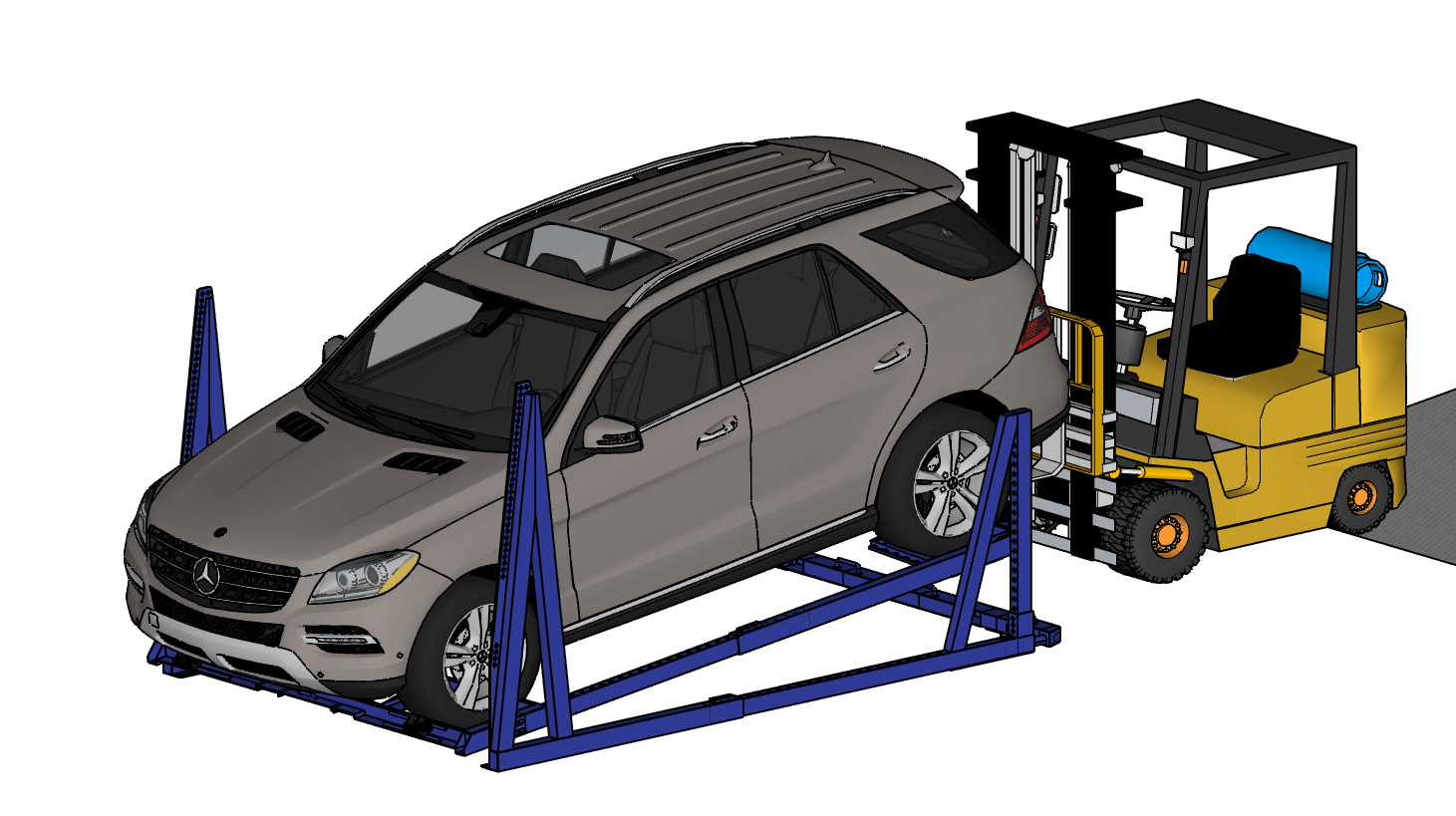

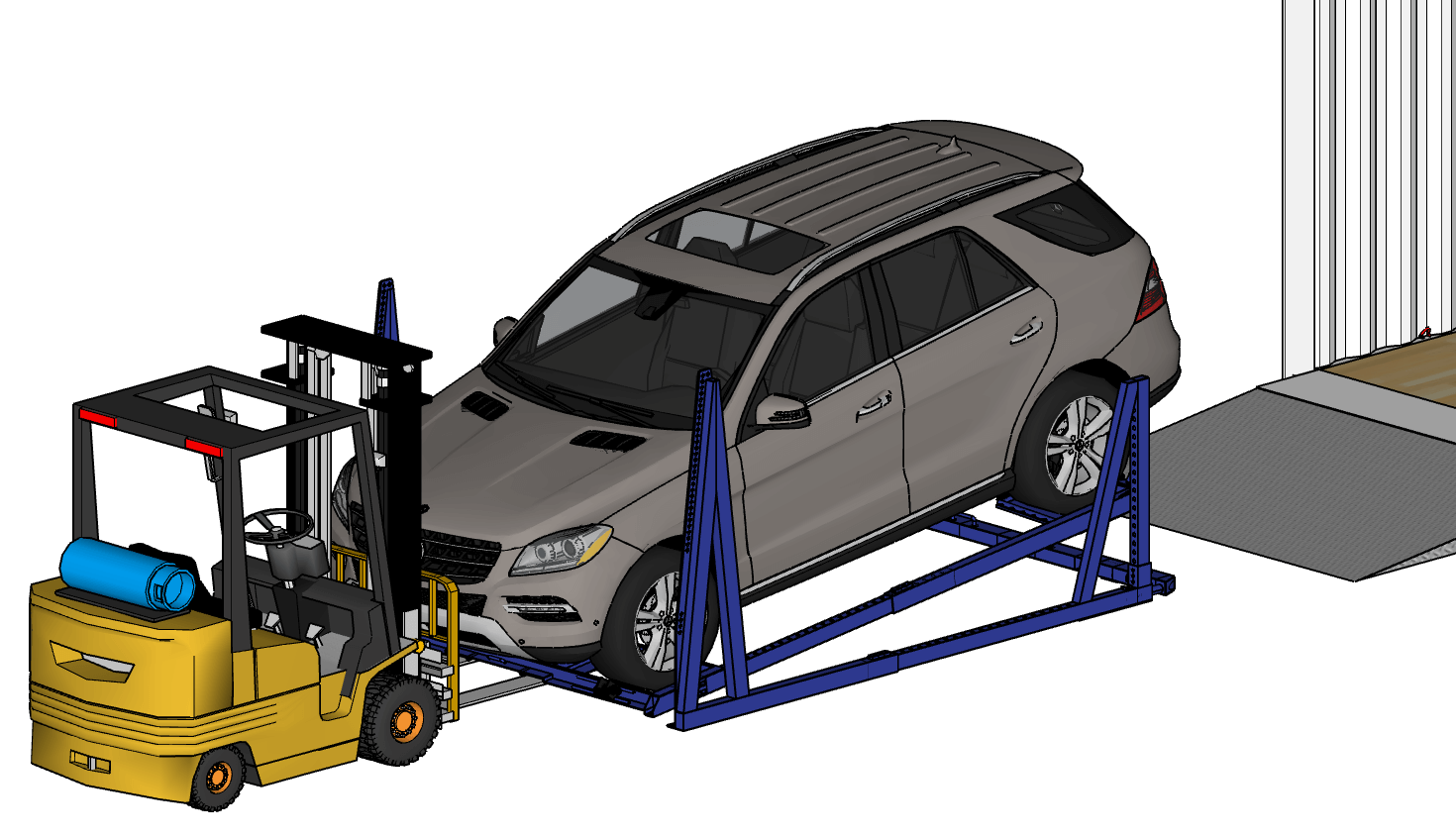

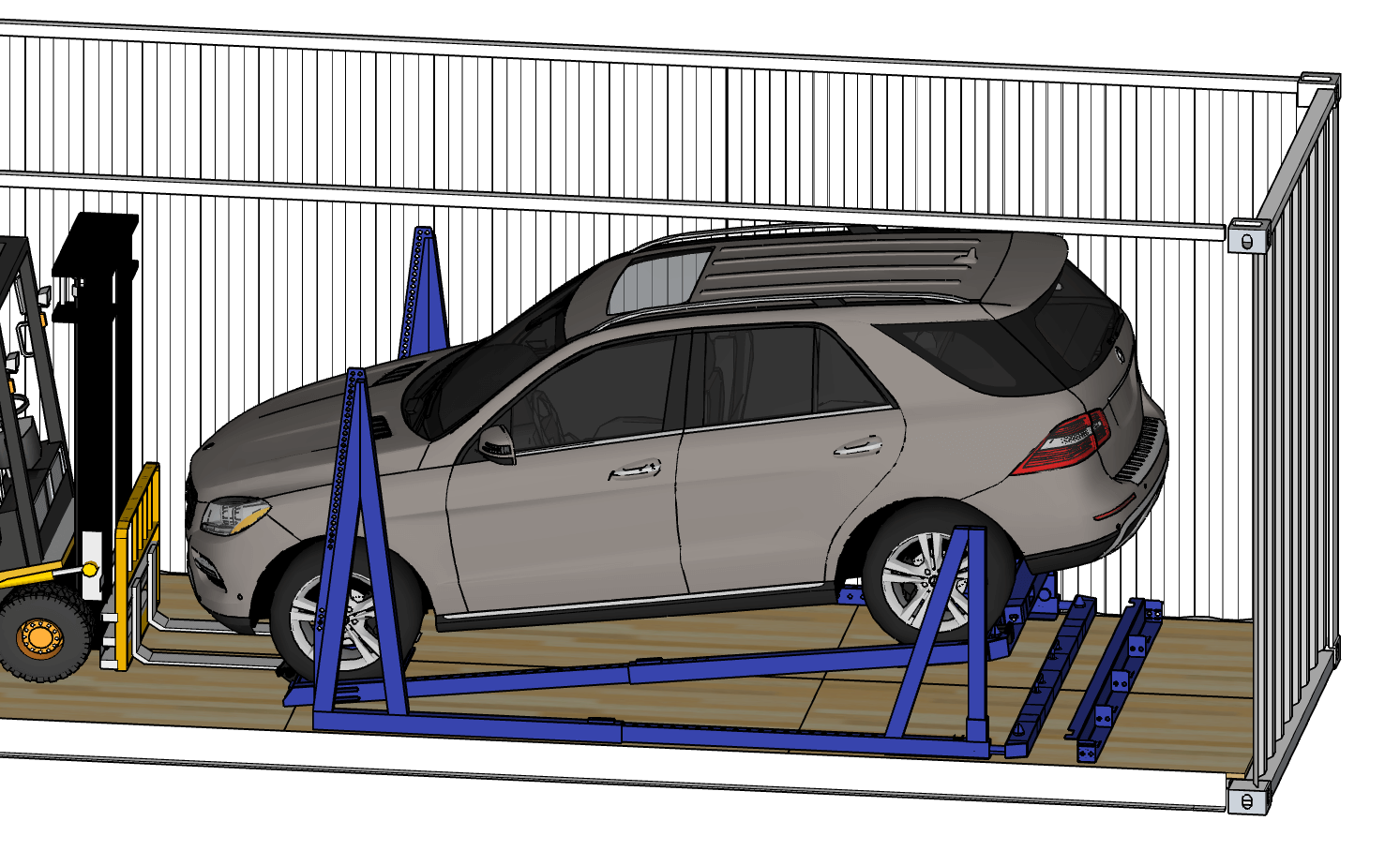

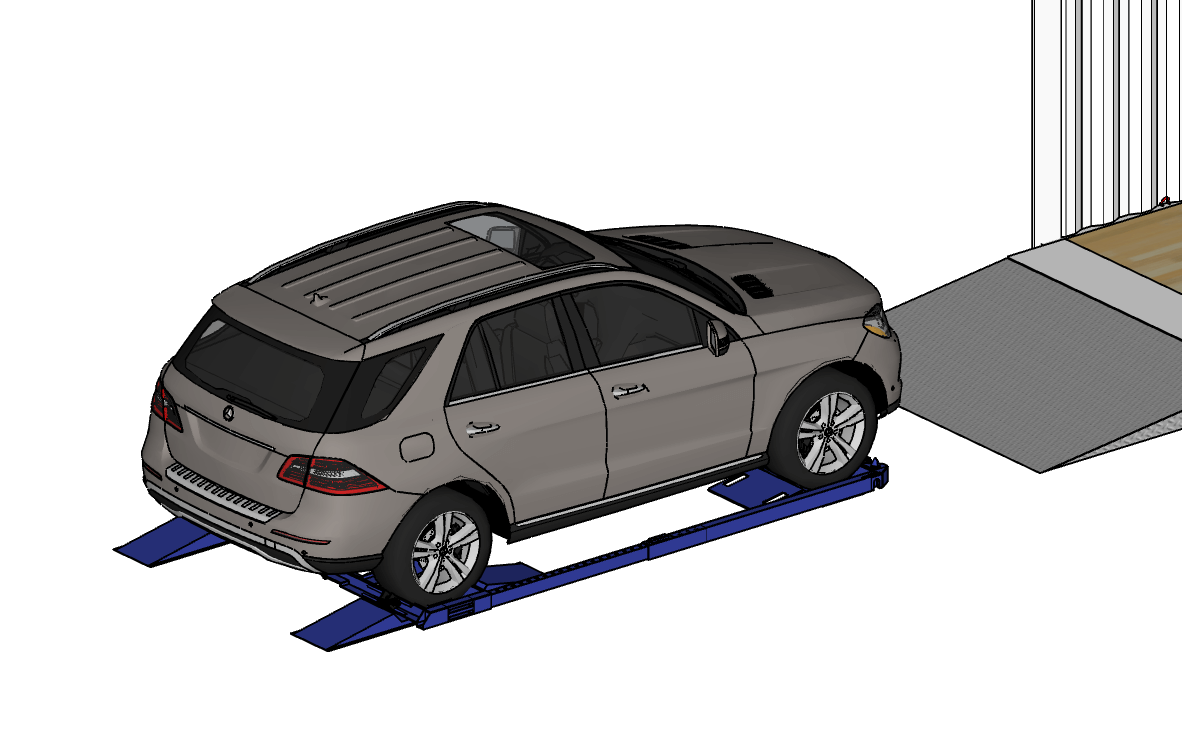

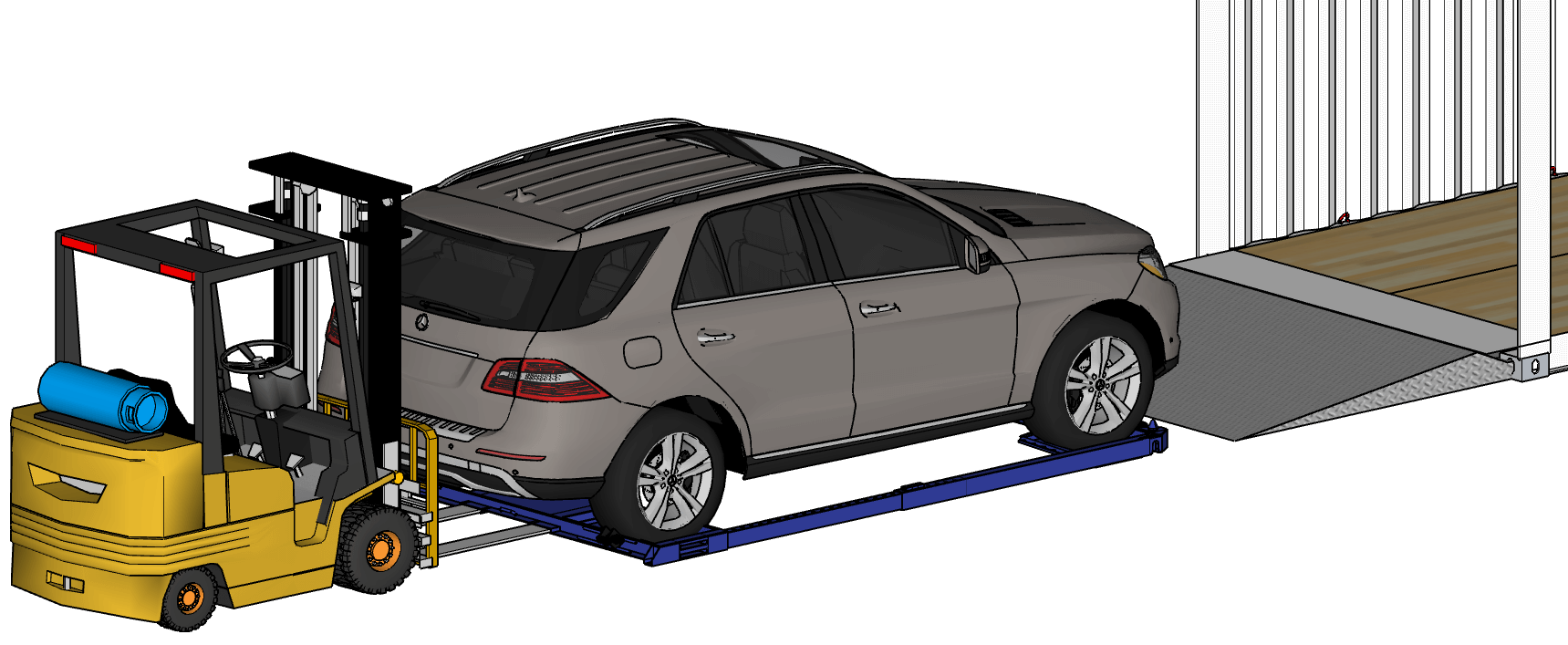

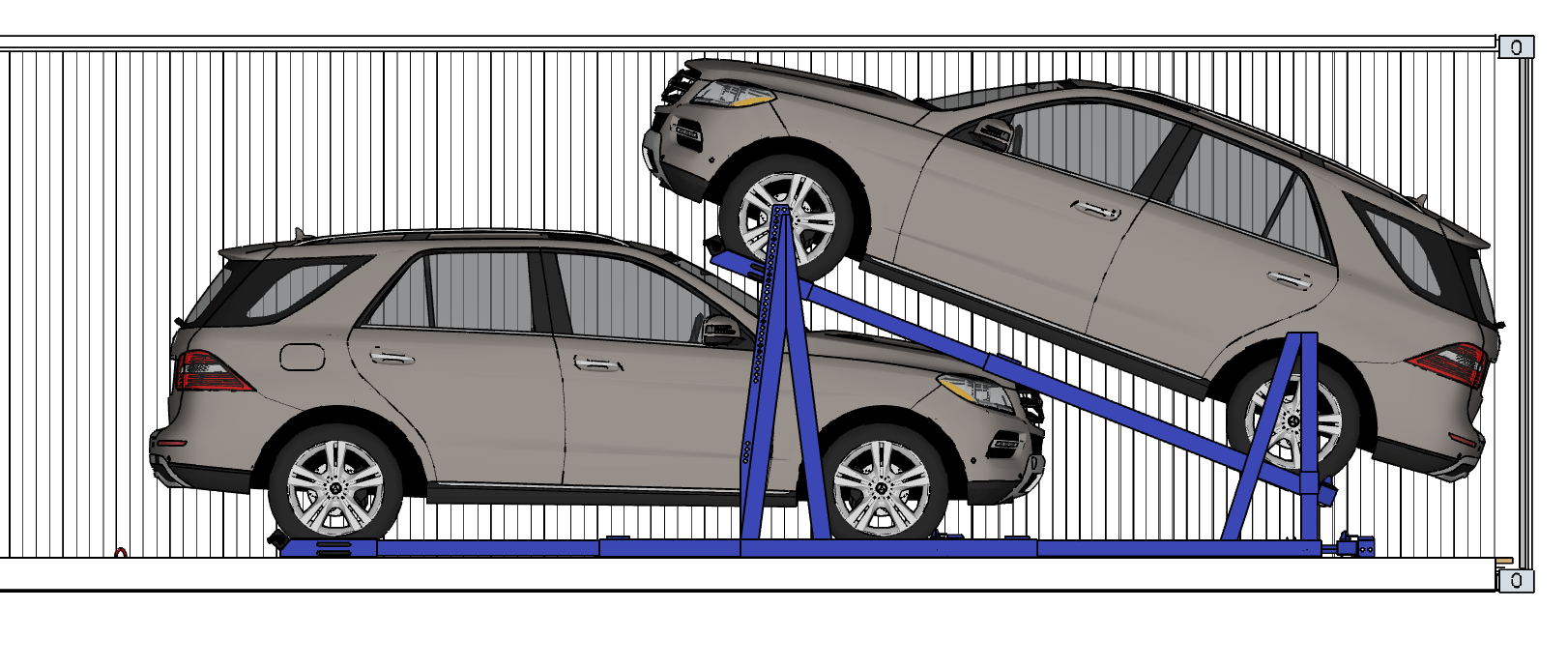

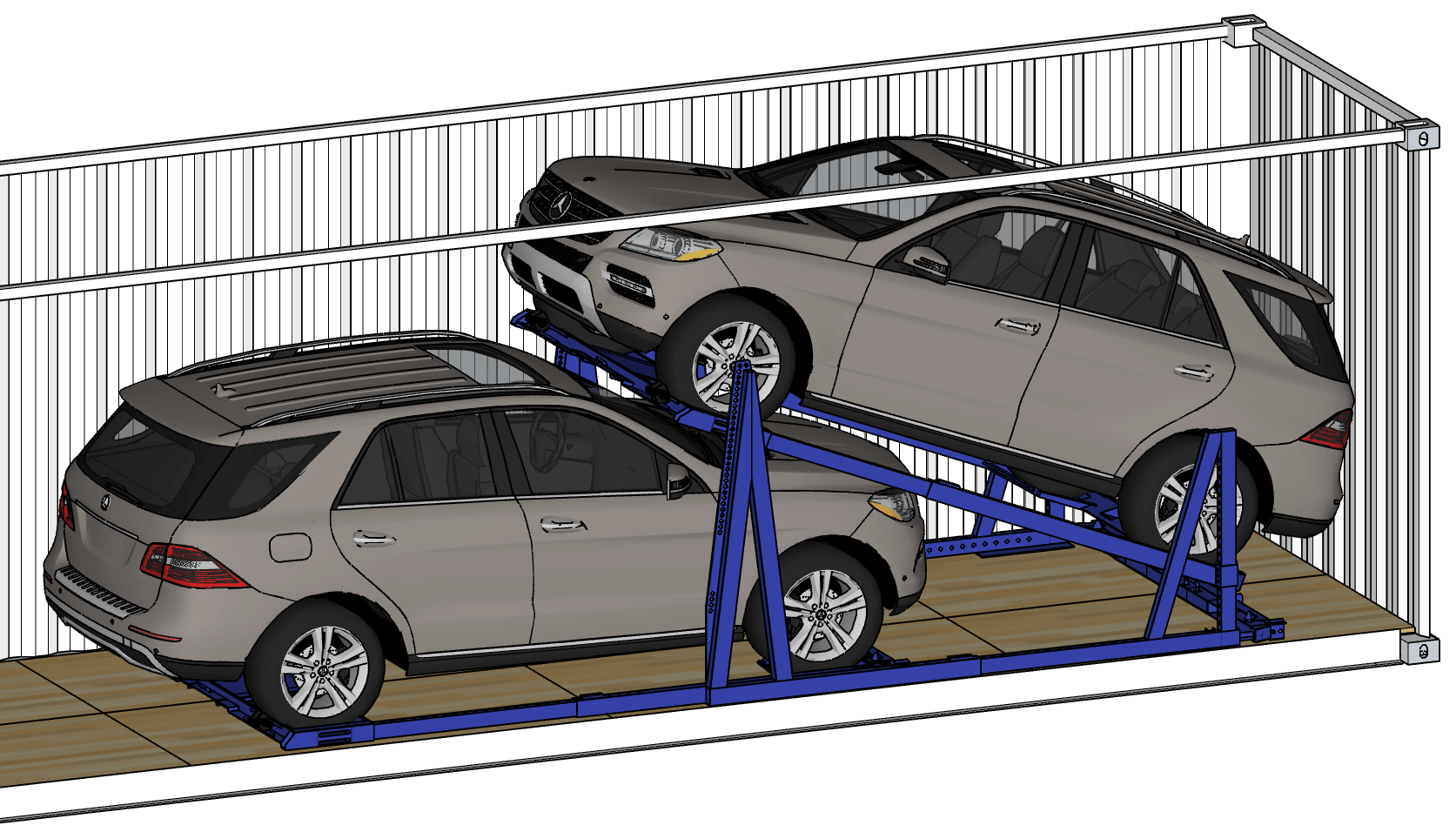

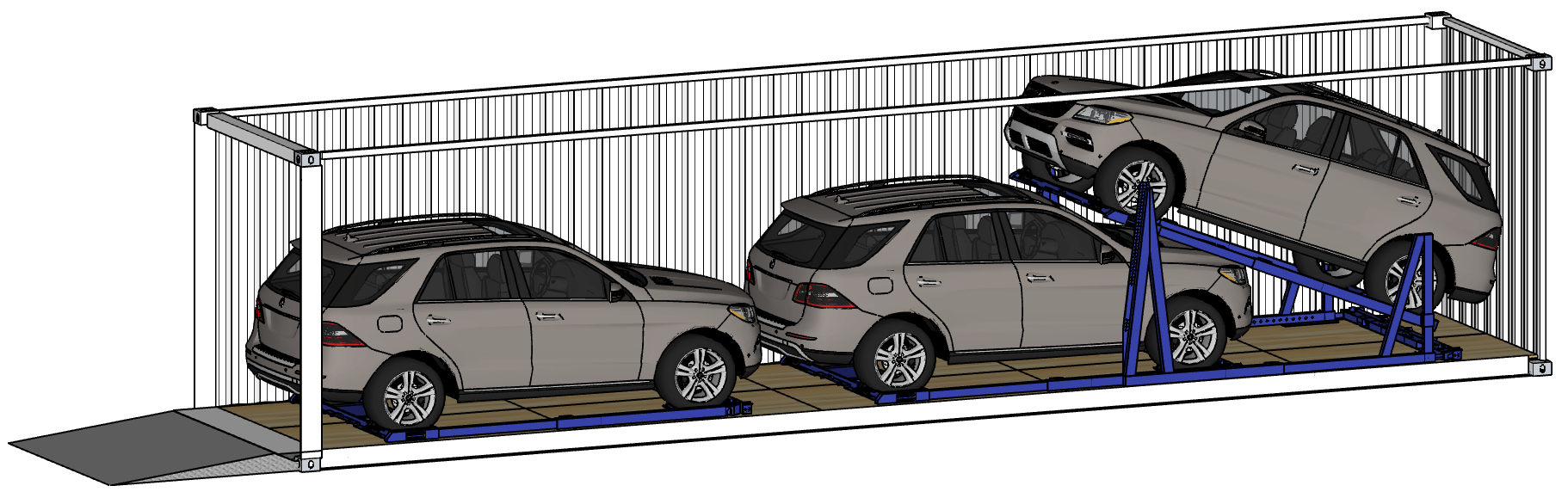

The EL-RAK is an innovative container racking system that allows cars to be loaded externally on wheeled cassettes, and then moved into place by forklift truck. Using an EL-RAK allows operators to securely load 3 to 4 cars in a 40 foot shipping container. The EL-RAK differs from our other solutions by allowing drivers to position their cars on the racking before being placed in the container.

Benefits of the EL-RAK

- It fits all makes and models of vehicle

- It allows you to transport combinations of different sizes of vehicle

- It fits all container sizes

- Lightweight

- Easy and fast to load

- Low operator skill required

- High rack return rates

- Common equipment for all loadings

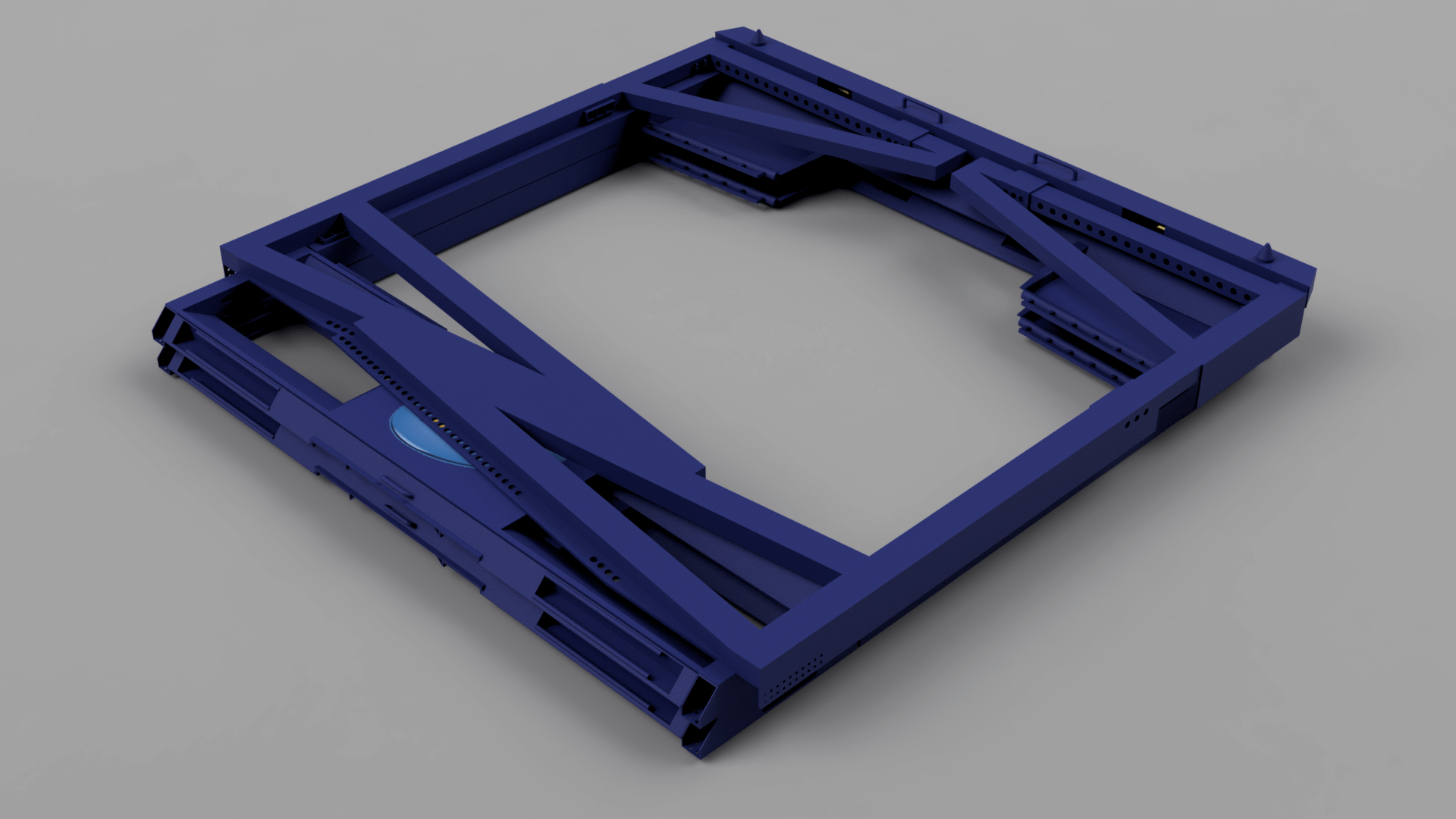

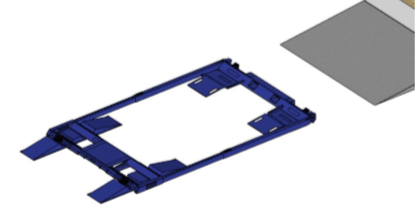

When collapsed, the EL-RAK pod will load up to 45 pods inside one 40ftHC container.

This efficiency minimises repositioning costs for the operator.

EL-RAK Vs Competitors

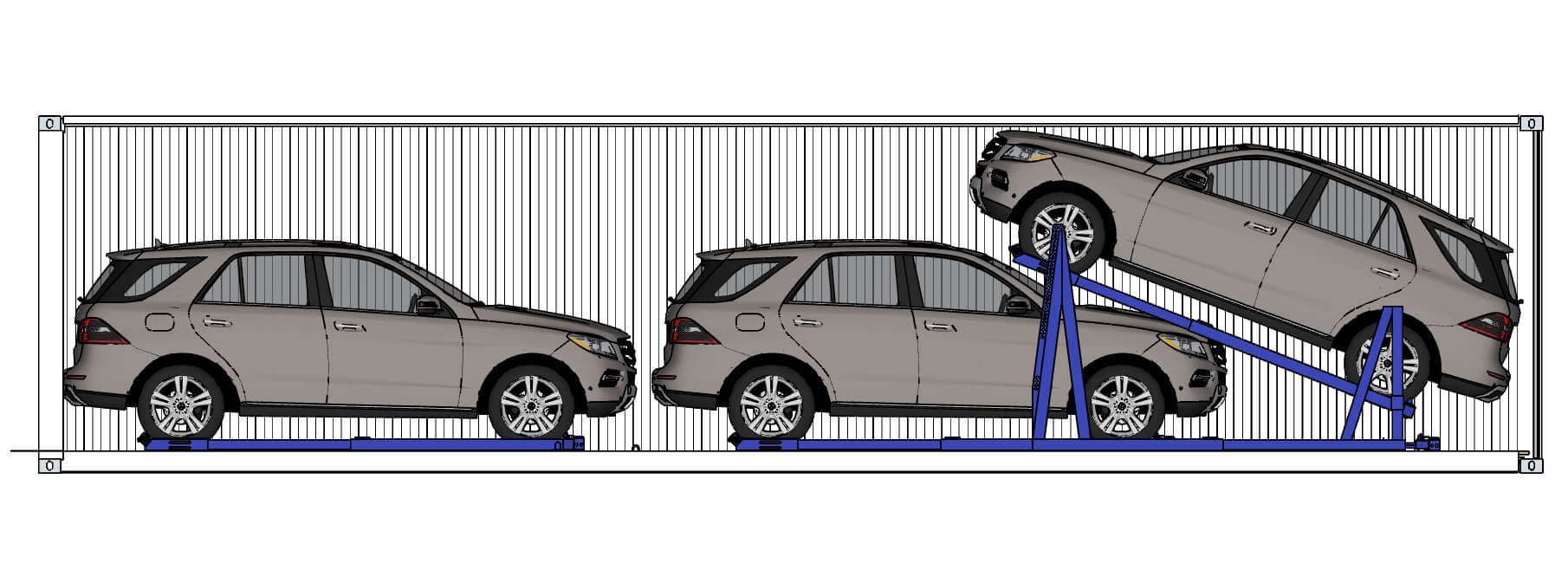

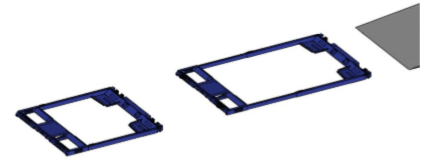

How does the EL-RAK offer a superior alternative to its competitors? The main difference is in the size and shape of the EL-RAK’s top and bottom cassettes. On competing systems, these are of different parts, restricting the carrying capacity of a container when shipping a mixed consignment of vehicles and making equipment relocation extremely difficult. On the EL-RAK both cassettes are the same; giving you greater flexibility for transporting different numbers and sizes of vehicles. To put it simply, the EL-RAK can load 4 small vehicles on a route in one direction and then the same equipment can be used to load 3 larger vehicles on the return leg of the journey.

The EL-RAK is also universally adaptable to any size shipping container. The racking can easily be adjusted to accommodate 45 or 53 foot shipping containers, standard height, high cube or super cube containers and standard width or pallet wide boxes. All without any risk as the vehicles are completely secured.

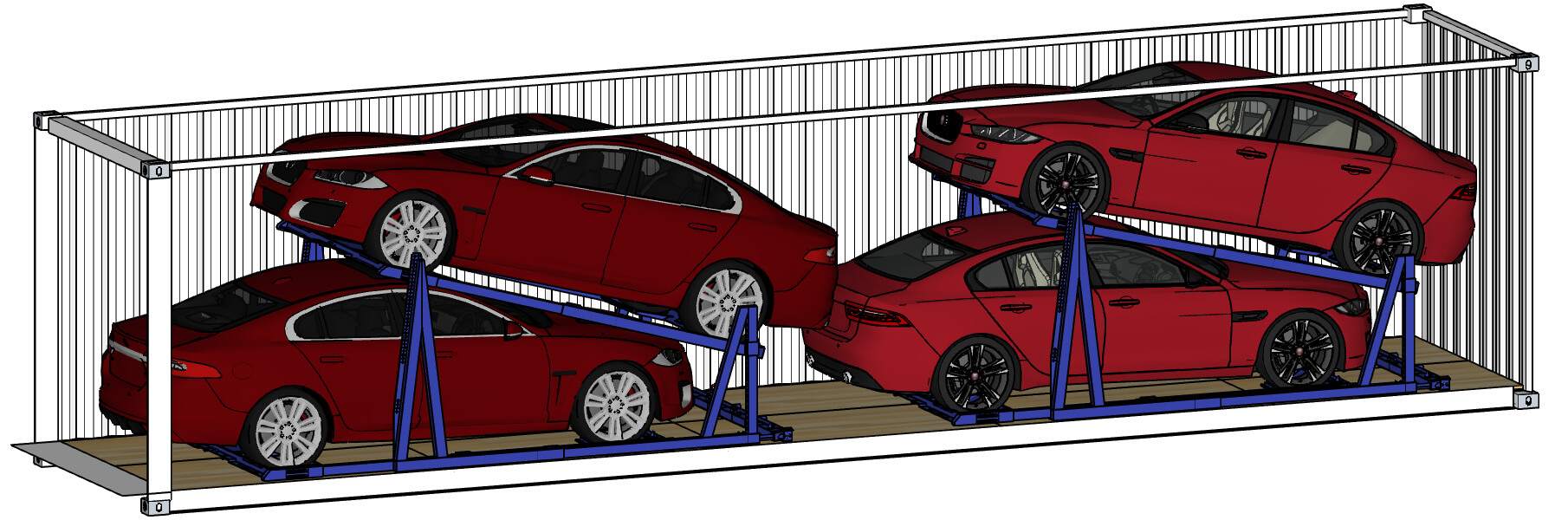

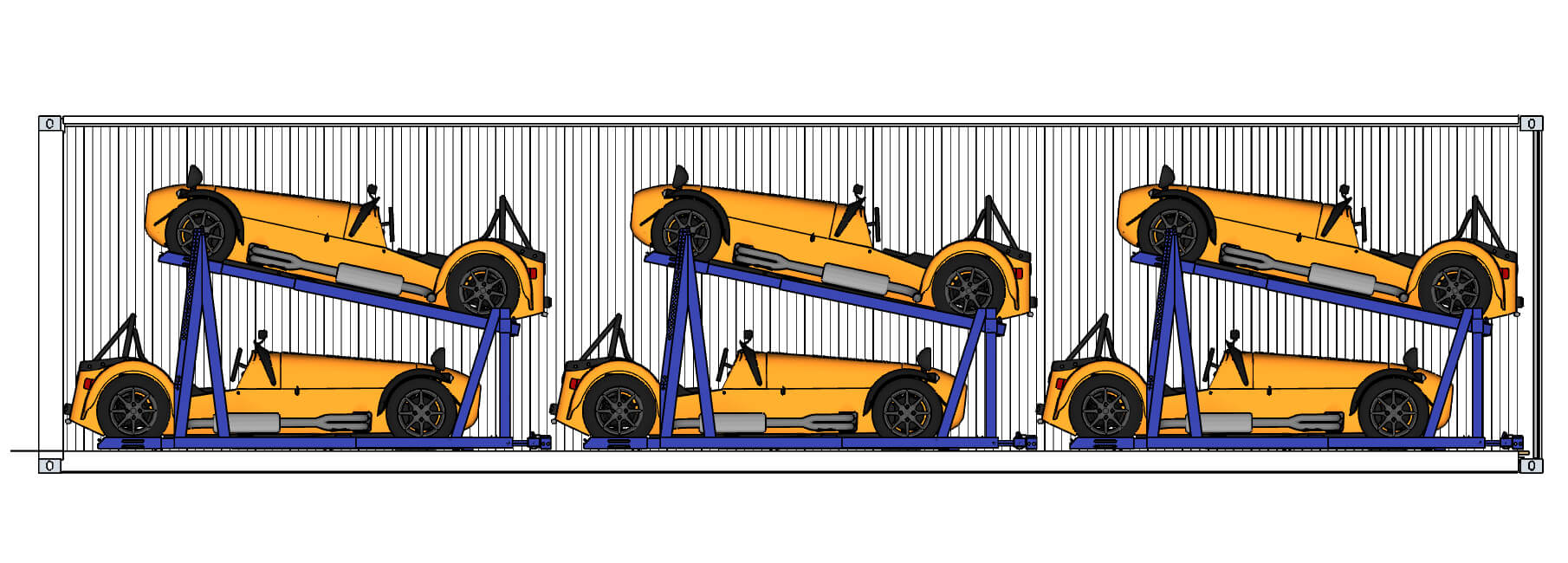

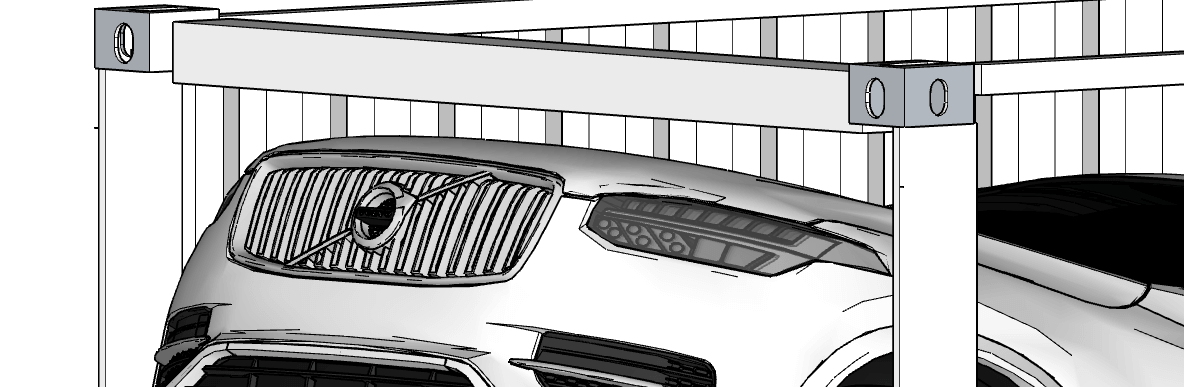

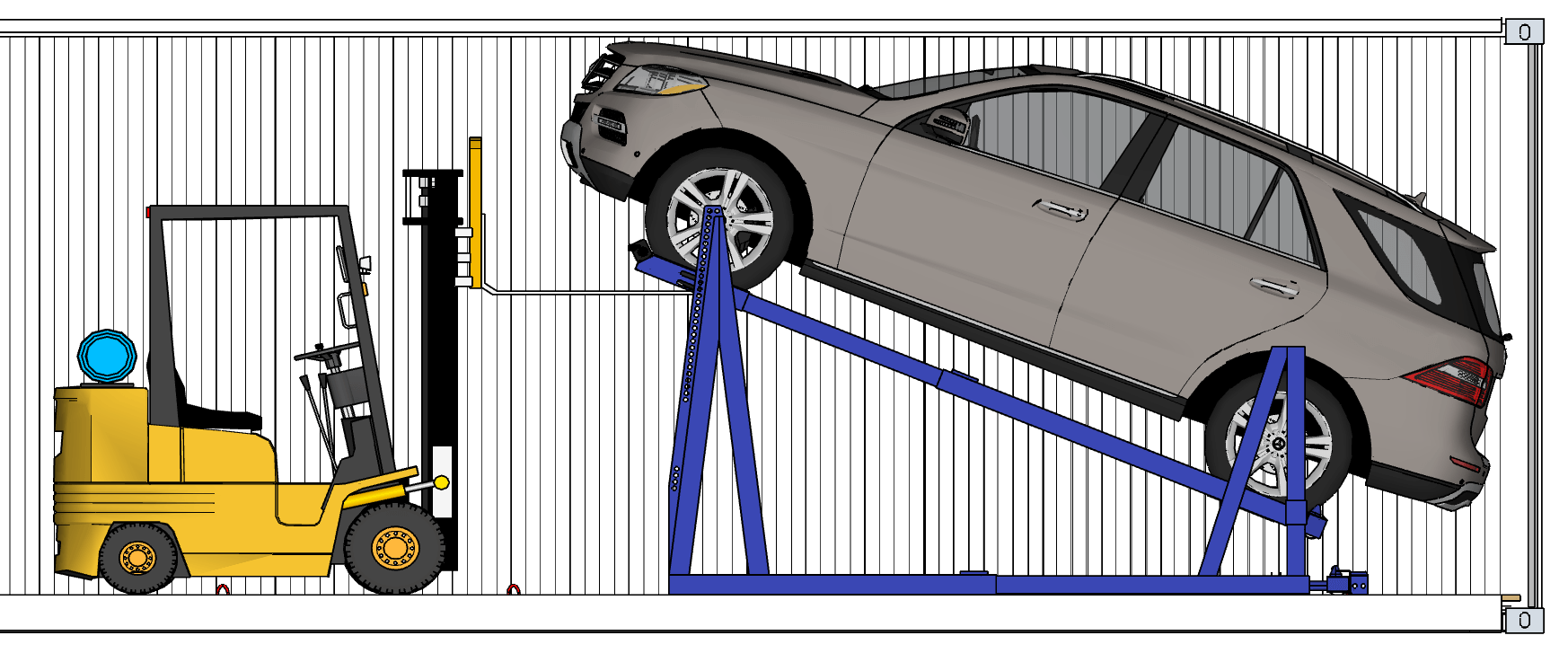

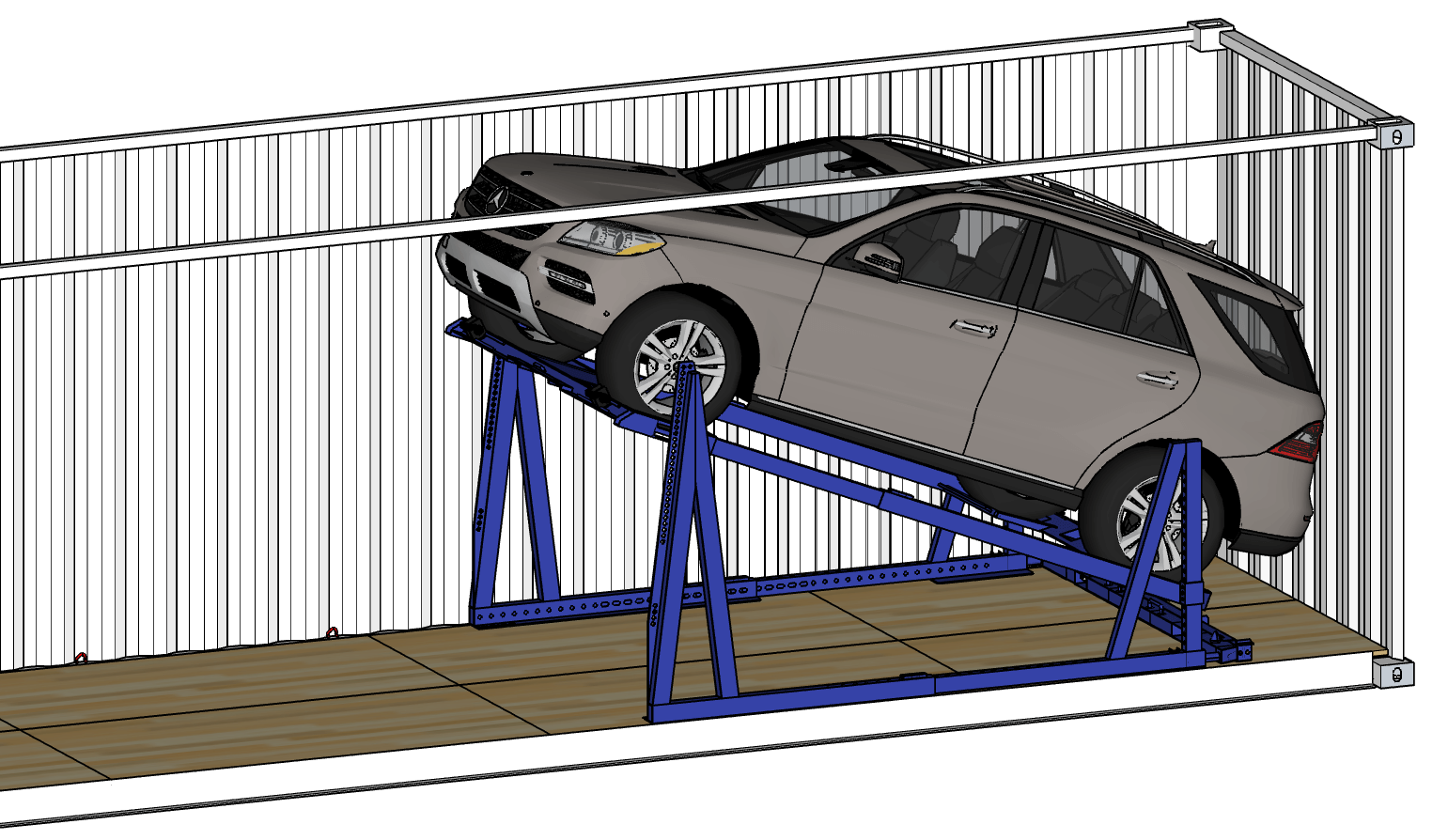

When loading the upper vehicles, the racking is moved into the container horizontally, rather than at an angle, and is only lifted to the transport position once inside the container. This maximises space utilisation by ensuring that vehicles are lifted as high as they can be inside the container, rather than being limited by the lower height of the header bar at the door of the container.

Once again, this helps you maximise load efficiency, streamline planning, and minimise the risk of damage.

Explanation

Competitors have to fit already lifted vehicles under the bar shown in the picture, leading to wasted space at the top of the container, which means the lower cars can’t nest as far underneath, therefore reducing the number of cars that can fit in one container.

Because we can lift up inside the container, our lifted cars can go higher (whilst keeping a safe distance to the roof)

To discuss the most appropriate solution for your business, please get in touch for a chat with one of our logistics experts today. Call us on +44(0) 1926 40 82 82, or send a message through our contact form.

The EL-RAK offers unparalleled loading flexibility. Because the upper and lower vehicles use common parts, the same equipment is required for any loading configuration. Loading 1 raised and 2 floor vehicles, or 2 raised and 1 floor vehicle, or 2 raised and 2 floor vehicles uses the same 2 parts – cassettes and bases. Whether you’re loading sports cars, SUVS, sedans, pickups or any combination of those, in 20ft, 40ft, 45ft or 53ft containers, it’s the same product.

How to Load

Useful Links

Quick Enquiry

Image Gallery